Bulk purchasing from a manufacturer can increase profit margins, improve supply stability, and help dealers scale faster. But it can also create serious risks if the supplier is unreliable, the product quality is inconsistent, or the terms are unclear. Many dealers lose money not because demand is low, but because they missed key checks before placing a large order.

This guide explains the most important questions dealers, distributors, importers, and wholesalers should ask manufacturers before bulk purchasing. It is written to help you reduce risk, protect your brand, and ensure long-term business success.

1) Product Quality and Materials

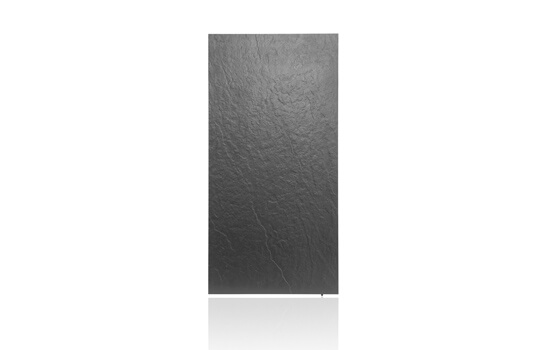

A bulk order is only profitable if product quality stays consistent across every batch. Dealers should confirm the manufacturer’s quality process, material specs, and testing methods.

Questions to ask:

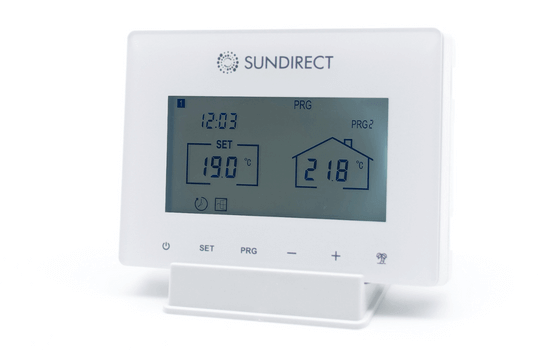

- What heating element type is used (carbon, quartz, ceramic, graphene, etc.)?

- What is the material of the panel body and surface coating?

- What is the warranty period and what failures are covered?

- What is the expected product lifespan under normal use?

- Do you perform 100% testing or sampling inspection?

- What are your QC checkpoints during production?

What to request:

- Product specification sheet (datasheet)

- Internal quality control checklist

- Warranty policy document

- Sample unit before mass production

2) Certifications and Compliance for Your Market

Every country has different electrical safety requirements. Dealers must confirm the manufacturer can legally supply products for their target market. Without correct certification, goods can be blocked at customs or rejected by retail platforms.

Questions to ask:

- What certifications do you already have for this product category?

- Can you provide certificates with valid test reports?

- Are the certifications issued under your factory name or a third party?

- Can the product be certified for my market if not already approved?

Common certifications to confirm:

- CE, RoHS, ERP (Europe)

- UKCA (United Kingdom)

- UL, ETL (USA/Canada)

- FCC (electronics if applicable)

- ISO 9001 (factory quality management)

What to request:

- Copies of certificates

- Lab test reports

- Compliance declarations

- Label and rating plate proof

3) Production Capacity and Lead Time

A common dealer problem is delayed delivery, especially in peak winter season. Dealers should verify the factory’s true production capability and confirm lead times under different scenarios.

Questions to ask:

- What is your monthly production capacity for this product?

- What is your current lead time for 500 units, 1,000 units, and 5,000 units?

- How do lead times change in peak season?

- Do you keep raw materials and components in stock?

- What happens if the factory faces delays?

What to request:

- Production schedule estimate

- Written lead-time terms in quotation or contract

- Peak-season planning confirmation

4) Pricing, MOQ, and Payment Terms

Bulk pricing only makes sense if the total landed cost supports your margins. Dealers should confirm full pricing details, MOQs per model, and payment protection.

Questions to ask:

- What is the MOQ per wattage and per model?

- Are there different MOQs for OEM/private label?

- What is the price difference between standard and customized products?

- What are the payment terms (T/T, LC, deposits)?

- Is the quoted price stable for future reorders?

What to request:

- Detailed quotation with all models and wattages

- Incoterms (EXW, FOB, CIF, DDP) clearly listed

- Breakdown of packaging cost and accessories cost

- Validity period of quotation

5) Customization and OEM/ODM Options

Dealers often increase sales by building their own brand. But OEM can create delays, design mistakes, and extra costs if not planned correctly.

Questions to ask:

- Can you provide private label branding and custom packaging?

- What customization options are available (color, size, wattage, control system)?

- What are the OEM setup fees and tooling costs?

- How long does OEM development take?

- Can you share OEM examples you have done before?

What to request:

- OEM catalog options

- Packaging templates

- Printing file requirements

- OEM timeline for sampling and mass production

6) After-Sales Support and Spare Parts

Dealers should confirm after-sales support clearly, especially if they will sell to retail consumers. Warranty without service support creates cost and reputation risk.

Questions to ask:

- How is warranty handled for bulk orders?

- Do you provide spare parts for repair or replacement?

- What is the claim process and required proof?

- Do you offer technical support documents for end customers?

- Do you provide installation guides and manuals?

What to request:

- Warranty claim procedure

- Spare parts list with cost

- User manual and installation guide

- Troubleshooting guide

7) Packaging, Labeling, and Brand Protection

Packaging affects customer perception and reduces shipping damage. Labeling is also legally required in many markets.

Questions to ask:

- What packaging is included in standard pricing?

- Can you provide drop-test packaging for e-commerce?

- Can the packaging include my branding and barcodes?

- What labeling is included (rating label, compliance marks, safety warnings)?

Can you add multi-language manuals?

What to request:

- Packaging photos

- Carton dimension and weight details

- Pallet packing details for container planning

- Labeling preview or sample label photo

8) Logistics and Export Experience

Export is not only about manufacturing. Many factories fail in documentation and shipment handling, causing delivery delays and customs issues.

Questions to ask:

- What countries do you already export to?

- Can you provide export documents correctly (invoice, packing list, COO)?

- Do you support sea freight and air freight packaging standards?

- Can you support DDP or only FOB/CIF?

- What is your standard container loading plan?

What to request:

- Sample export documents

- HS code guidance

- Container loading plan

- Shipping marks and carton labels format

9) Risk Protection for Dealers

A bulk order should be protected with clear agreements. Dealers should confirm the manufacturer’s responsibility and what happens if issues occur.

Questions to ask:

- What is your policy if products fail quality inspection?

- What is the process if shipment is damaged or missing items?

- Can you support third-party inspection before shipping?

- Do you sign purchase contracts with penalties for late delivery?

- Do you provide exclusivity options for my region?

What to request:

- Written terms and conditions

- Inspection agreement option

- Replacement and compensation policy

- NDA for OEM brand protection

10) Sample Order and Testing Before Bulk

The most reliable dealers never place bulk orders without sampling and testing. A sample order proves product performance, packaging, and delivery reliability.

Questions to ask:

- Can you provide 1–3 samples for testing before bulk?

- Can you customize sample branding for evaluation?

- How long does sample delivery take?

- Is the sample identical to mass production quality?

What to request:

- Sample invoice

- Sample specification and test report

- Sample packaging proof

Conclusion

Bulk purchasing from a manufacturer is a strategic decision, not only a price decision. Dealers who ask the right questions gain better control over quality, delivery, compliance, and long-term profitability. Before placing any large order, confirm product quality, certifications, factory capacity, pricing terms, OEM support, after-sales service, and logistics reliability.

A well-checked manufacturer partnership reduces returns, protects your brand, and builds a stable supply chain for future growth.

FAQs

Certifications ensure the product meets safety and legal requirements in your target market. Without proper certification, shipments can be blocked at customs or rejected by retailers and e-commerce platforms.

Product quality consistency is the most important. Dealers should verify material specs, testing methods, failure rates, and warranty coverage, then confirm with sample testing before mass production.

Dealers can reduce risk by ordering samples first, confirming certifications, using third-party inspections, demanding written warranty terms, and ensuring the manufacturer has proven export experience.

A proper quotation should include product models, wattages, MOQ, unit price, packaging details, accessories, lead time, payment terms, and Incoterms such as FOB or CIF.

Yes. Warranty claims and after-sales issues can become costly. Dealers should confirm spare parts availability, warranty claim procedures, replacement policy, and technical support resources before bulk purchase.